Qinhong Automation Technology overcomes cotton baling challenges, propelling the industry forward.

2025-06-07

In the field of cotton baling, persistent thorny issues such as bale explosion, "white egg" formation, aging resistance, and temperature difference tolerance have severely affected cotton quality and transportation safety. Recently, Qingdao Qinhong Automation Equipment Co., Ltd. has successfully solved these problems with its advanced fully automatic cotton baling film tape and double-sided adhesive equipment, providing new solutions for the cotton industry.

Qinhong Automation's equipment adopts advanced automation technology, fundamentally changing the traditional application method of double-sided adhesive tape when wrapping cotton with baling film. Regarding aging resistance, the company's R&D team has conducted extensive experiments and research, adopting an exclusive formula. This formula enables the product to perform in extreme temperature differences from -20℃ to 60℃, consistently maintaining excellent adhesion. Taking Australia's cotton-producing regions as an example, where day-night temperature differences are extreme, with summer temperatures reaching over 50℃ and winter lows dropping below 0℃, using the double-sided adhesive tape produced by Qinhong Automation equipment for cotton baling ensures bale stability during long-term storage and transportation, effectively preventing bale explosions.

To address the "white egg" problem, the equipment ensures uniform adhesion between the double-sided adhesive and the tape through precise control and advanced technology, preventing cotton from loosening and forming "white eggs" due to insufficient local adhesion. In cotton processing plants in the Xinjiang region, the cotton loss rate due to "white egg" issues previously reached as high as approximately 5%. After using Qinhong equipment, this loss rate has been reduced to less than 1%, saving enterprises significant economic losses.

In terms of temperature difference tolerance, the products manufactured by the equipment also perform exceptionally well. Whether in cold Canadian cotton-producing regions or hot Indian cotton-growing areas, they can withstand extreme temperature tests. Their unique formula and process ensure stable physical properties of the product in various temperature environments, preventing issues such as reduced adhesion or material embrittlement due to temperature changes.

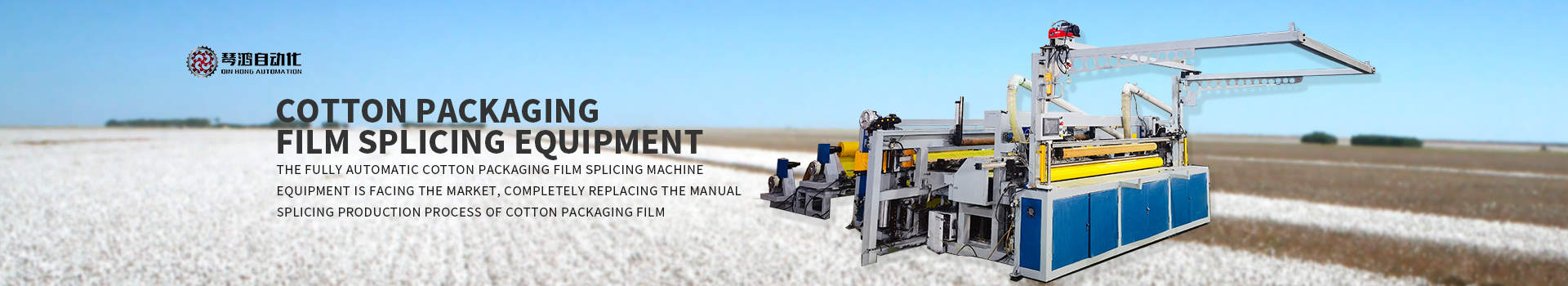

Additionally, Qinhong Automation customizes tapes and double-sided adhesives specifically for cotton baling scenarios both domestically and internationally. These products not only boast excellent performance but also achieve perfection in details such as adhesion. Coupled with the company's fully automatic cotton baling film splicing equipment, a complete solution is formed from cotton baling film production to the final baling stage, significantly improving cotton baling efficiency and quality, and propelling the entire cotton industry towards a more efficient and stable direction. With the promotion and application of this equipment and related products in the global market, it will undoubtedly bring new development opportunities and transformations to the cotton industry.

Mr.Huang

Mr.Shi

Business address: Xijiao Industrial Park, Huanxiu Street, Jimo District, Qingdao, Shandong Province

Email:821914288@qq.com