Enhancing Efficiency with Cotton Packing Film Machines: A Comprehensive Guide

2025-04-06

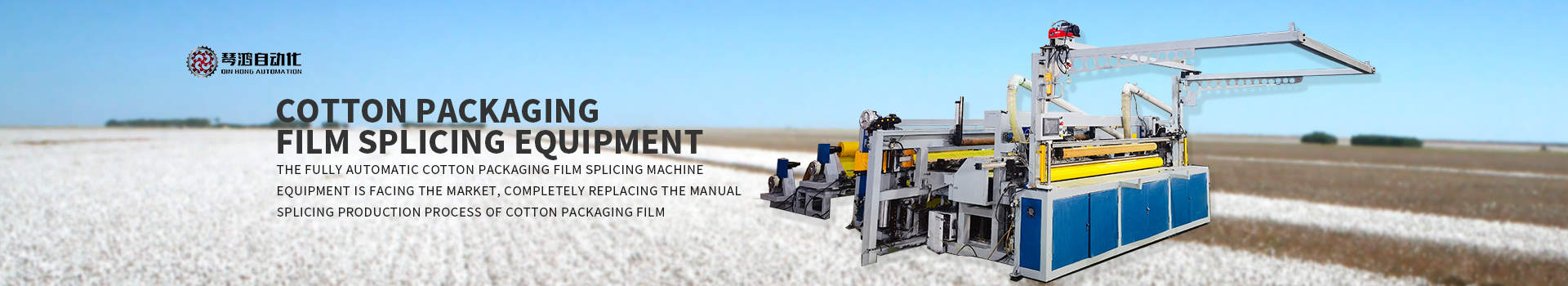

In the manufacturing and packaging sectors, efficiency and quality control are paramount. One vital piece of equipment that contributes to these goals is the cotton packing film machine. These machines are specifically designed to wrap and package products using cotton-based films, ensuring protection and enhancing visual appeal. Let's explore the intricacies of cotton packing film machines and their importance in the packaging industry.

At the core of a cotton packing film machine’s functionality is its ability to create secure and attractive packaging for various products. This equipment works by feeding cotton film into a wrapping system that envelops the item, using heat or adhesive to seal the package. The result is a finished product that is not only visually appealing but also well-protected from environmental factors, ensuring better shelf-life and customer satisfaction.

One of the key advantages of utilizing cotton packing film machines is their versatility. They can cater to a wide range of products, from textiles and apparel to food items and fragile goods. This flexibility makes them a valuable addition to any manufacturing operation, allowing businesses to expand their product range without investing in multiple packaging systems.

Another benefit of these machines is their efficiency. Automated cotton packing film machines can significantly reduce packaging time compared to manual methods. This not only speeds up the production process but also minimizes labor costs. By increasing the speed and accuracy of the packaging process, manufacturers can meet higher demand without compromising on quality.

Moreover, using cotton-based films aligns with the growing trend towards sustainability. Consumers are increasingly looking for eco-friendly packaging options, and cotton films offer a biodegradable alternative to traditional plastics. By incorporating cotton packing film machines into production lines, businesses can not only enhance their operational efficiency but also appeal to environmentally conscious consumers.

To optimize the use of cotton packing film machines, businesses should consider several best practices. Regular maintenance is crucial to ensure the machine operates smoothly and efficiently; this includes routine cleaning and inspection of components. Additionally, investing in staff training will ensure operators understand the machinery's capabilities and can troubleshoot minor issues before they escalate.

In conclusion, cotton packing film machines are an essential asset for manufacturers looking to boost their packaging efficiency and meet modern consumer demands. By understanding their functionality and implementing best practices, businesses can leverage these machines to enhance their overall production capabilities while promoting sustainability in their operations. Integrating cotton packing film technology can lead to a more streamlined, profitable, and environmentally friendly packaging process.

At the core of a cotton packing film machine’s functionality is its ability to create secure and attractive packaging for various products. This equipment works by feeding cotton film into a wrapping system that envelops the item, using heat or adhesive to seal the package. The result is a finished product that is not only visually appealing but also well-protected from environmental factors, ensuring better shelf-life and customer satisfaction.

One of the key advantages of utilizing cotton packing film machines is their versatility. They can cater to a wide range of products, from textiles and apparel to food items and fragile goods. This flexibility makes them a valuable addition to any manufacturing operation, allowing businesses to expand their product range without investing in multiple packaging systems.

Another benefit of these machines is their efficiency. Automated cotton packing film machines can significantly reduce packaging time compared to manual methods. This not only speeds up the production process but also minimizes labor costs. By increasing the speed and accuracy of the packaging process, manufacturers can meet higher demand without compromising on quality.

Moreover, using cotton-based films aligns with the growing trend towards sustainability. Consumers are increasingly looking for eco-friendly packaging options, and cotton films offer a biodegradable alternative to traditional plastics. By incorporating cotton packing film machines into production lines, businesses can not only enhance their operational efficiency but also appeal to environmentally conscious consumers.

To optimize the use of cotton packing film machines, businesses should consider several best practices. Regular maintenance is crucial to ensure the machine operates smoothly and efficiently; this includes routine cleaning and inspection of components. Additionally, investing in staff training will ensure operators understand the machinery's capabilities and can troubleshoot minor issues before they escalate.

In conclusion, cotton packing film machines are an essential asset for manufacturers looking to boost their packaging efficiency and meet modern consumer demands. By understanding their functionality and implementing best practices, businesses can leverage these machines to enhance their overall production capabilities while promoting sustainability in their operations. Integrating cotton packing film technology can lead to a more streamlined, profitable, and environmentally friendly packaging process.

Mr.Huang

Mr.Shi

Business address: Xijiao Industrial Park, Huanxiu Street, Jimo District, Qingdao, Shandong Province

Email:821914288@qq.com