Customer service

We are committed to improving product quality based on industry requirements and customer standards

Technical support

We are currently focusing on the research and development of non-standard equipment in response to the requirements of national low energy consumption and high standards

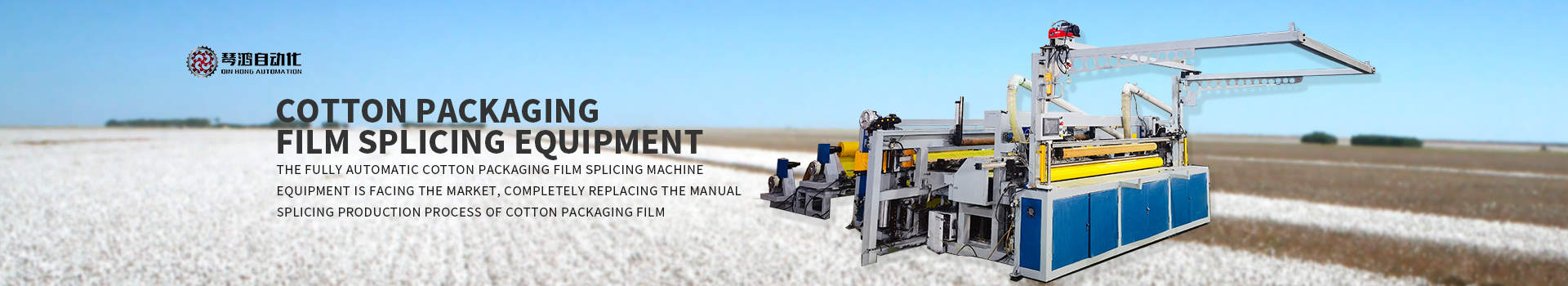

We aim to meet the needs of both international and domestic markets, and under the premise of national strategic goals, we lead our team members to work hard day and night, taking a year. The fully automatic cotton packaging film splicing machine equipment is facing the market, completely replacing the manual splicing production process of cotton packaging film. Compared to previous manual production, we have achieved a doubling of production volume and a halving of energy consumption, The personnel have also changed from the previous production line consisting of five people to one person controlling the production process, which has also played a crucial role in reducing production costs for enterprises and cotton farmers, truly realizing the policy of benefiting the people and farmers

Service team

We are committed to improving product quality based on industry requirements and customer standards

2019-2025

In 2019, Qingdao Qinhong responded to national strategies and spent 365 days overcoming core technologies for fully automatic cotton packing film splicing machines. The product was launched in 2020, setting an industry record of "one-person operation, doubled production, and halved energy consumption": a 5-person production line was reduced to 1 operator, with the production cost per roll of film dropping by 40%. The equipment integrates functions such as automatic labeling and intelligent edge trimming, holding invention patents that fill global technological gaps, and has become the only globally certified supporting solution for John Deere CP690/770 cotton pickers.

In 2021, the upgraded inkjet gluing equipment innovatively applied a servo metering system to achieve 2.2-meter fixed-length gluing with 2 cm interval QR code labeling. Combined with intelligent double-sided tape recognition technology, it reduced the package explosion rate from the industry average of 12% to 3.6%.

The latest upgrade in 2023 introduced an AI visual monitoring system, which uses 3D visual recognition technology to real-time detect splicing accuracy. The abnormal warning response speed has been upgraded to 0.3 seconds, further optimizing the process flow.

After 8 years of deep cultivation, the company has sold 150 units globally, covering major cotton-producing regions in the United States, China, Australia, and Brazil, assisting in the production of 5 million rolls of high-strength packing film worldwide. It has established a full-process technical barrier covering film blowing, gluing, and RFID tracking.

2021-2025

In 2025, Qingdao Qinhong launched the high-efficiency fully automatic pre-punched water hose equipment in response to the industrial trend of "low energy consumption and high standards". This equipment revolutionizes traditional production modes: workers only need to feed water hose raw materials into the machine, and the rest of the processes are fully automated — five ultrasonic punching machines perform precise operations while achieving automatic heat sealing and winding. With a production efficiency 3 times higher than similar competitors and no manual intervention required throughout, it significantly enhances large-scale production efficiency.

Featuring a modular intelligent design, the equipment can customize five-hole pre-punched water hoses to adapt to diverse scenarios such as agricultural irrigation and industrial water transportation. Its core technical breakthrough lies in: using a servo system to accurately control punching positions and spacing, combined with intelligent heat sealing technology, to ensure uniform hole diameters, stable structure, and strong water pressure resistance in the hoses. Meanwhile, energy consumption is reduced, fully meeting the upgrading needs of modern enterprises for "cost reduction, efficiency improvement, and green production".

Mr.Huang

Mr.Shi

Business address: Xijiao Industrial Park, Huanxiu Street, Jimo District, Qingdao, Shandong Province

Email:821914288@qq.com