Revolutionizing Packaging: The Role of Cotton Packing Film Machines in Modern Manufacturing

2025-03-27

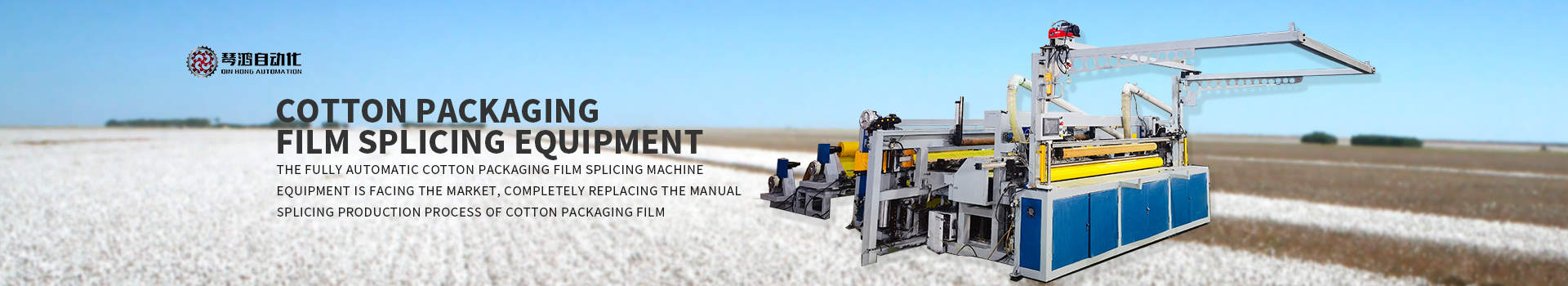

In the ever-evolving manufacturing landscape, the cotton packing film machine stands out as a significant development within the packaging machinery sector. This machine is designed to create packaging solutions that utilize cotton-based films, which are not only biodegradable but also offer versatile applications in various industries. The demand for environmentally friendly packaging solutions has surged, making cotton packing film machines increasingly relevant in today's market.

The primary function of a cotton packing film machine is to produce high-quality packaging materials that meet the diverse needs of manufacturers. This machine typically operates by unwinding cotton-based films and transforming them into various shapes and sizes, allowing for customized packaging solutions. The versatility of cotton films makes them suitable for packaging a wide range of products, from textiles to food items, thus broadening their application scope.

One of the key benefits of utilizing a cotton packing film machine is its contribution to sustainability. As more companies strive to reduce their carbon footprint, the use of biodegradable materials like cotton becomes a strategic advantage. Unlike traditional plastic packaging, cotton films decompose naturally, alleviating concerns associated with pollution and landfill waste. By adopting cotton packaging solutions, businesses can enhance their brand image as eco-conscious entities, catering to a growing demographic of environmentally aware consumers.

In addition to environmental benefits, cotton packing film machines also offer operational efficiencies. These machines are designed to streamline the packaging process, reducing labor costs and minimizing waste. With advancements in technology, many modern cotton packing film machines come equipped with automation features that enhance speed and precision. This allows manufacturers to increase output without compromising on quality, ultimately leading to higher profitability.

Moreover, the integration of cotton packing film machines into existing production lines can lead to improved product presentation. The aesthetic appeal of cotton packaging can enhance the perceived value of products, making them more attractive to consumers. This is particularly important in competitive markets where packaging can significantly influence purchasing decisions.

In conclusion, the cotton packing film machine represents a transformative solution for manufacturers looking to innovate their packaging processes. By embracing this technology, companies can not only meet rising consumer demand for sustainable products but also improve operational efficiency and product appeal. As the industry progresses, the adoption of cotton packing film machines is likely to become a standard practice, shaping the future of packaging in a more environmentally responsible direction.

The primary function of a cotton packing film machine is to produce high-quality packaging materials that meet the diverse needs of manufacturers. This machine typically operates by unwinding cotton-based films and transforming them into various shapes and sizes, allowing for customized packaging solutions. The versatility of cotton films makes them suitable for packaging a wide range of products, from textiles to food items, thus broadening their application scope.

One of the key benefits of utilizing a cotton packing film machine is its contribution to sustainability. As more companies strive to reduce their carbon footprint, the use of biodegradable materials like cotton becomes a strategic advantage. Unlike traditional plastic packaging, cotton films decompose naturally, alleviating concerns associated with pollution and landfill waste. By adopting cotton packaging solutions, businesses can enhance their brand image as eco-conscious entities, catering to a growing demographic of environmentally aware consumers.

In addition to environmental benefits, cotton packing film machines also offer operational efficiencies. These machines are designed to streamline the packaging process, reducing labor costs and minimizing waste. With advancements in technology, many modern cotton packing film machines come equipped with automation features that enhance speed and precision. This allows manufacturers to increase output without compromising on quality, ultimately leading to higher profitability.

Moreover, the integration of cotton packing film machines into existing production lines can lead to improved product presentation. The aesthetic appeal of cotton packaging can enhance the perceived value of products, making them more attractive to consumers. This is particularly important in competitive markets where packaging can significantly influence purchasing decisions.

In conclusion, the cotton packing film machine represents a transformative solution for manufacturers looking to innovate their packaging processes. By embracing this technology, companies can not only meet rising consumer demand for sustainable products but also improve operational efficiency and product appeal. As the industry progresses, the adoption of cotton packing film machines is likely to become a standard practice, shaping the future of packaging in a more environmentally responsible direction.

Mr.Huang

Mr.Shi

Business address: Xijiao Industrial Park, Huanxiu Street, Jimo District, Qingdao, Shandong Province

Email:821914288@qq.com